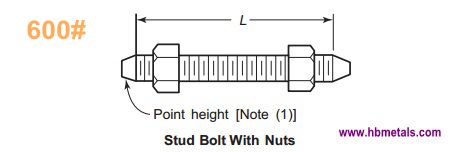

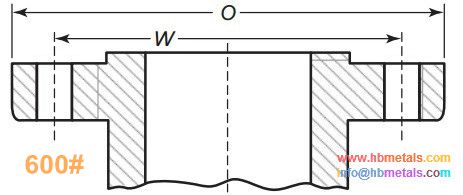

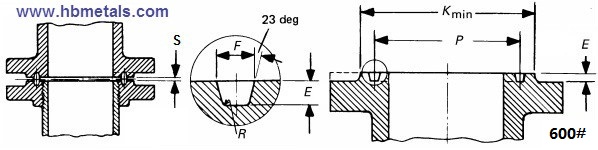

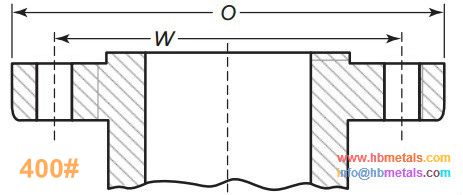

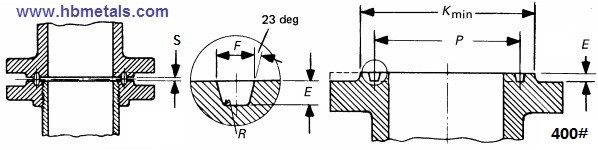

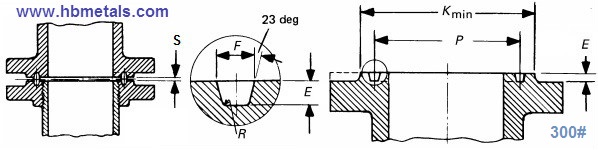

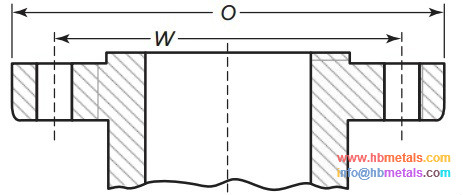

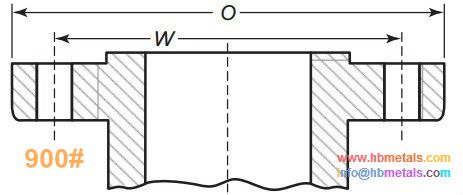

1. Technical drawings of flange bolting for Class 900 ASME B16.5 flanges.

2. Dimensions of flange bolting for Class 900 ASME B16.5 flanges.

| NPS | O inch mm | W inch mm | m inch | n | d inch | L1 inch mm | L2 inch mm | L3 inch mm |

|---|---|---|---|---|---|---|---|---|

| 1/2" | 4.75 120 | 3.25 82.6 | 7/8 | 4 | 3/4 | 4.25 110 | 4.00 100 | 4.25 110 |

| 3/4" | 5.12 130 | 3.50 88.9 | 7/8 | 4 | 3/4 | 4.50 115 | 4.25 110 | 4.50 115 |

| 1" | 5.88 150 | 4.00 101.6 | 1 | 4 | 7/8 | 5.00 125 | 4.75 120 | 5.00 125 |

| 1 1/4" | 6.25 160 | 4.38 111.1 | 1 | 4 | 7/8 | 5.00 125 | 4.75 120 | 5.00 125 |

| 1 1/2" | 7.00 180 | 4.88 123.8 | 1 1/8 | 4 | 1 | 5.50 140 | 5.25 135 | 5.50 140 |

| 2" | 8.50 215 | 6.50 165.1 | 1 | 8 | 7/8 | 5.75 145 | 5.50 140 | 5.75 145 |

| 2 1/2" | 9.62 245 | 7.50 190.5 | 1 1/8 | 8 | 1 | 6.25 160 | 6.00 150 | 6.25 160 |

| 3" | 9.50 240 | 7.50 190.5 | 1 | 8 | 7/8 | 5.75 145 | 5.50 140 | 5.75 145 |

| 4" | 11.50 290 | 9.25 235.0 | 1 1/4 | 8 | 1 1/8 | 6.75 170 | 6.50 165 | 6.75 170 |

| 5" | 13.75 350 | 11.00 279.4 | 1 3/8 | 8 | 1 1/4 | 7.50 190 | 7.25 185 | 7.50 190 |

| 6" | 15.00 380 | 12.50 317.5 | 1 1/4 | 12 | 1 1/8 | 7.50 190 | 7.25 185 | 7.75 195 |

| 8" | 18.50 470 | 15.50 393.7 | 1 1/2 | 12 | 1 3/8 | 8.75 220 | 8.50 215 | 8.75 220 |

| 10" | 21.50 545 | 18.50 469.9 | 1 1/2 | 16 | 1 3/8 | 9.25 235 | 9.00 230 | 9.25 235 |

| 12" | 24.00 610 | 21.00 533.4 | 1 1/2 | 20 | 1 3/8 | 10.00 255 | 9.75 250 | 10.00 255 |

| 14" | 25.25 640 | 22.00 558.8 | 1 5/8 | 20 | 1 1/2 | 10.75 275 | 10.50 265 | 11.00 280 |

| 16" | 27.75 705 | 24.25 616.0 | 1 3/4 | 20 | 1 5/8 | 11.25 285 | 11.00 280 | 11.50 290 |

| 18" | 31.00 785 | 27.00 685.8 | 2 | 20 | 1 7/8 | 12.75 325 | 12.50 320 | 13.25 335 |

| 20" | 33.75 855 | 29.50 749.3 | 2 1/8 | 20 | 2 | 13.75 350 | 13.50 345 | 14.25 360 |

| 24" | 41.00 1040 | 35.50 901.7 | 2 5/8 | 20 | 2 1/2 | 17.25 440 | 17.00 430 | 18.00 455 |

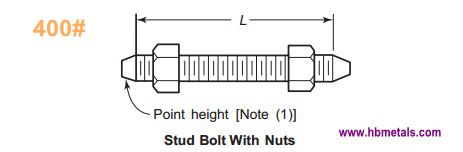

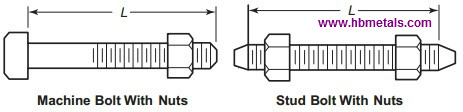

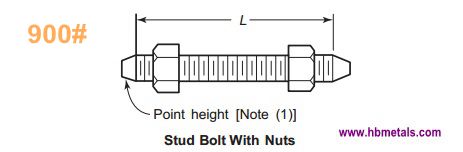

1. For the denotation of dimensions “NPS, O, W, m, n, d, L1, L2, L3”, please refer to that of flange bolting for Class 600. The length of the stud bolt doesn’t include the height of the points.

2. The bolting of ASME B16.5 class 900 flanges can be furnished as stud bolts with nuts. Stud bolts can be used for flanges with either raised face or ring joint face. All dimensions are provided in mm and inch units.

| ASME B16.5 Flange Bolting Specification by Classes | ||||||

|---|---|---|---|---|---|---|

| Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |