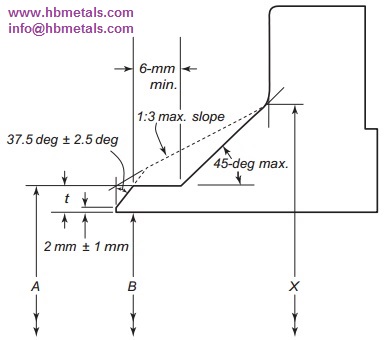

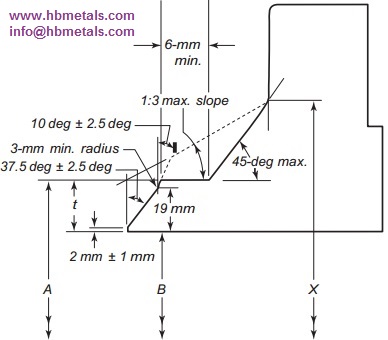

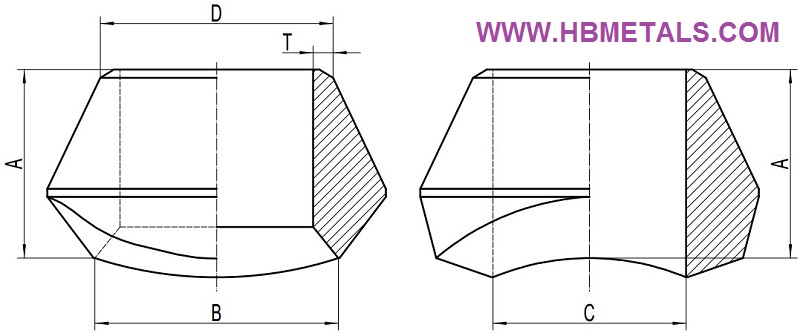

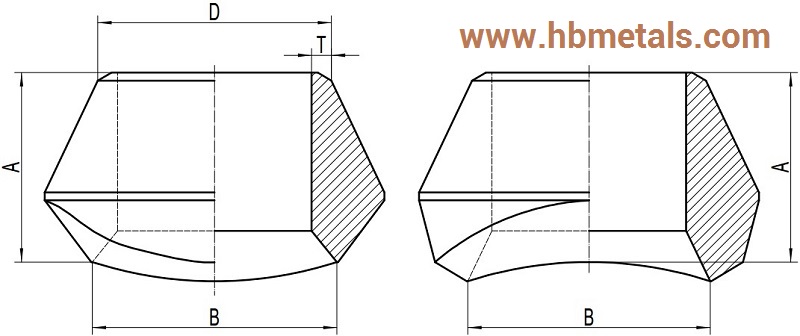

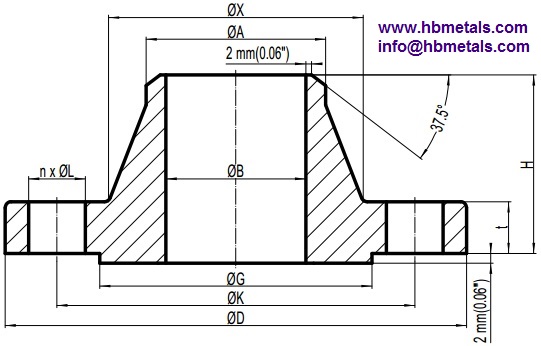

Technical drawing of ASME B16.5 weld neck flanges 150LB.

Dimension and weight specifications of ASME B16.5 Weld Neck flanges 150LB.

| NPS | D inch mm | K inch mm | G inch mm | B inch mm | A inch mm | X inch mm | n | L inch | t inch mm | H inch mm | Wt. lbs kgs |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2" | 3.50 90 | 2.38 60.3 | 1.38 34.9 | 0.62 15.8 | 0.84 21.3 | 1.19 30 | 4 | 5/8 | 0.38 9.6 | 1.81 46 | 1.10 0.48 |

| 3/4" | 3.88 100 | 2.75 69.9 | 1.69 42.9 | 0.82 20.9 | 1.05 26.7 | 1.50 38 | 4 | 5/8 | 0.44 11.2 | 2.00 51 | 1.62 0.71 |

| 1" | 4.25 110 | 3.12 79.4 | 2.00 50.8 | 1.05 26.6 | 1.32 33.4 | 1.94 49 | 4 | 5/8 | 0.50 12.7 | 2.12 54 | 2.21 1.02 |

| 1-1/4" | 4.62 115 | 3.50 88.9 | 2.50 63.5 | 1.38 35.1 | 1.66 42.2 | 2.31 59 | 4 | 5/8 | 0.56 14.3 | 2.19 56 | 2.90 1.33 |

| 1-1/2" | 5.00 125 | 3.88 98.4 | 2.88 73.0 | 1.61 40.9 | 1.90 48.3 | 2.56 65 | 4 | 5/8 | 0.62 15.9 | 2.38 60 | 3.82 1.75 |

| 2" | 6.00 150 | 4.75 120.7 | 3.62 92.1 | 2.07 52.5 | 2.38 60.3 | 3.06 78 | 4 | 3/4 | 0.69 17.5 | 2.44 62 | 5.70 2.58 |

| 2-1/2" | 7.00 180 | 5.50 139.7 | 4.12 104.8 | 2.47 62.7 | 2.88 73.0 | 3.56 90 | 4 | 3/4 | 0.81 20.7 | 2.69 68 | 9.11 4.13 |

| 3" | 7.50 190 | 6.00 152.4 | 5.00 127.0 | 3.07 77.9 | 3.50 88.9 | 4.25 108 | 4 | 3/4 | 0.88 22.3 | 2.69 68 | 10.80 4.92 |

| 3-1/2" | 8.50 215 | 7.00 177.8 | 5.50 139.7 | 3.55 90.1 | 4.00 101.6 | 4.81 122 | 8 | 3/4 | 0.88 22.3 | 2.75 70 | 13.40 6.08 |

| 4" | 9.00 230 | 7.50 190.5 | 6.19 157.2 | 4.03 102.3 | 4.50 114.3 | 5.31 135 | 8 | 3/4 | 0.88 22.3 | 2.94 75 | 15.10 6.84 |

| 5" | 10.00 255 | 8.50 215.9 | 7.31 185.7 | 5.05 128.2 | 5.56 141.3 | 6.44 164 | 8 | 7/8 | 0.88 22.3 | 3.44 87 | 18.90 8.56 |

| 6" | 11.00 280 | 9.50 241.3 | 8.50 215.9 | 6.07 154.1 | 6.63 168.3 | 7.56 192 | 8 | 7/8 | 0.94 23.9 | 3.44 87 | 23.30 10.60 |

| 8" | 13.50 345 | 11.75 298.5 | 10.62 269.9 | 7.98 202.7 | 8.63 219.1 | 9.69 246 | 8 | 7/8 | 1.06 27.0 | 3.94 100 | 38.80 17.70 |

| 10" | 16.00 405 | 14.25 362.0 | 12.75 323.8 | 10.02 254.6 | 10.75 273.0 | 12.00 305 | 12 | 1 | 1.12 28.6 | 3.94 100 | 53.00 24.00 |

| 12" | 19.00 485 | 17.00 431.8 | 15.00 381.0 | 12.00 304.8 | 12.75 323.8 | 14.38 365 | 12 | 1 | 1.19 30.2 | 4.44 113 | 80.40 36.50 |

| 14" | 21.00 535 | 18.75 476.3 | 16.25 412.8 | - | 14.00 355.6 | 15.75 400 | 12 | 1-1/8 | 1.31 33.4 | 4.94 125 | 107.0 48.40 |

| 16" | 23.50 595 | 21.25 539.8 | 18.50 469.9 | - | 16.00 406.4 | 18.00 457 | 16 | 1-1/8 | 1.38 35.0 | 4.94 125 | 134.0 60.60 |

| 18" | 25.00 635 | 22.75 577.9 | 21.00 533.4 | - | 18.00 457.0 | 19.88 505 | 16 | 1-1/4 | 1.50 38.1 | 5.44 138 | 151.2 68.4 |

| 20" | 27.50 700 | 25.00 635.0 | 23.00 584.2 | - | 20.00 508.0 | 22.00 559 | 20 | 1-1/4 | 1.62 41.3 | 5.64 143 | 187.00 84.82 |

| 24" | 32.00 815 | 29.50 749.3 | 27.25 692.2 | - | 24.00 610.0 | 26.12 663 | 20 | 1-3/8 | 1.81 46.1 | 5.94 151 | 253.0 115.0 |

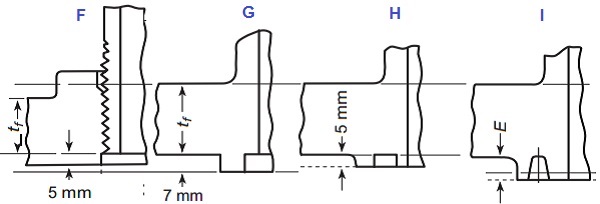

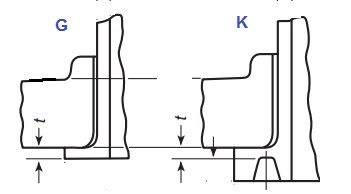

(1) 150LB refers to Class 150 which is one of the pressure ratings stipulated by ASME B16.5. Dimensions D, B, t and H refer to the basic flange dimensions: D – outside diameter of flange, B – bore diameter of weld neck flange, t – minimum thickness of flange, H – length through hub of weld neck flange. n, L and K refer to the bolting drilling dimensions of flange: n – number of bolts, L – diameter of bolt holes, K – diameter of bolt circle. G denotes the outside diameter of raised face. A and X are dimensions associated with the hub: A – diameter at the top of hub, X – diameter at the root of hub. A is the same as the nominal outside diameter of the pipe connected to the flange.

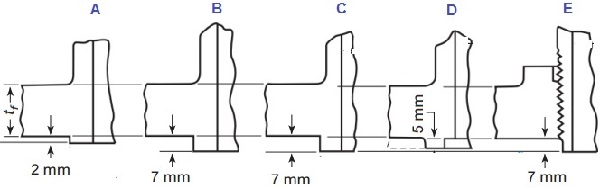

(2) Usually two types of welding ends can be furnished according to different wall thickness of the pipe. The bore diameters of weld neck flanges 150LB correspond to the inside diameters of pipe as given in ASME B36.10 for standard(STD) wall pipe. Thickness of standard wall is the same as SCH40 in sizes 10″ and smaller. These bore sizes are furnished unless otherwise specified by the purchaser. Besides, bore diameters of 14″ and larger shall be specified by the purchaser. Ring joint facing (RTJ) is also available upon request. All tolerances shall be in accordance with ASME B16.5.

(3) All dimensions are provided in both metric and imperial units except for the bolt hole dimensions. Each value of the two systems shall be used separately.