ASTM A182 F5 flanges are forged flanges manufactured from a chromium-molybdenum low alloy steel know as 5Cr-0.5Mo with a UNS designation of K41545. They are widely utilized in pressure high-temperature services such as oil refineries, chemical and petrochemical industries, power plant piping, heat exchangers, and various pressure vessels.

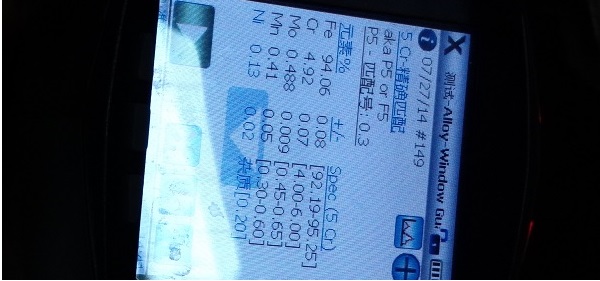

Chemical composition of ASTM A182 Gr. F5

| C | Mn | P | S | Si | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|

| 0.15 max | 0.30~0.60 | 0.030 max | 0.030 max | 0.50 max | 0.50 max | 4.0~6.0 | 0.44~0.65 |

Mechanical requirements and heat treatment.

| Tensile Strength, min, ksi [MPa] | Yield Strength, min, kis [MPa] | Elongation, min, % | Reduction of Area, min, % | Brinell Hardness, HBW |

|---|---|---|---|---|

| 70 [485] | 40 [275] | 20 | 35 | 143~217 |

Pressure-Temperature ratings for ASTM A182 F5 flanges.

| Temp. °C | Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |

|---|---|---|---|---|---|---|---|

| -29~38 | 19.8 | 51.7 | 68.9 | 103.4 | 155.1 | 258.6 | 430.9 |

| 50 | 19.5 | 51.5 | 68.7 | 103.0 | 154.5 | 257.5 | 429.2 |

| 100 | 17.7 | 50.4 | 67.3 | 100.9 | 151.3 | 252.2 | 420.4 |

| 150 | 15.8 | 48.2 | 64.2 | 96.4 | 144.5 | 240.9 | 401.5 |

| 200 | 13.8 | 46.3 | 61.7 | 92.5 | 138.8 | 231.3 | 385.6 |

| 250 | 12.1 | 44.8 | 59.8 | 89.6 | 134.5 | 224.1 | 373.5 |

| 300 | 10.2 | 42.9 | 57.0 | 85.7 | 128.6 | 214.4 | 357.1 |

| 325 | 9.3 | 41.4 | 55.0 | 82.6 | 124.0 | 206.6 | 344.3 |

| 350 | 8.4 | 40.3 | 53.6 | 80.4 | 120.7 | 201.1 | 335.3 |

| 375 | 7.4 | 38.9 | 51.6 | 77.6 | 116.5 | 194.1 | 323.2 |

| 400 | 6.5 | 36.5 | 48.9 | 73.3 | 109.8 | 183.1 | 304.9 |

| 425 | 5.5 | 35.2 | 46.5 | 70.0 | 105.1 | 175.1 | 291.6 |

| 450 | 4.6 | 33.7 | 45.1 | 67.7 | 101.4 | 169.0 | 281.8 |

| 475 | 3.7 | 27.9 | 37.1 | 55.7 | 83.6 | 139.3 | 232.1 |

| 500 | 2.8 | 21.4 | 28.5 | 42.8 | 64.1 | 106.9 | 178.2 |

| 538 | 1.4 | 13.7 | 18.3 | 27.4 | 41.1 | 68.6 | 114.3 |

| 550 | - | 12.0 | 16.1 | 24.1 | 36.1 | 60.2 | 100.4 |

| 575 | - | 8.8 | 11.7 | 17.6 | 26.4 | 44.0 | 73.4 |

| 600 | - | 6.1 | 8.1 | 12.1 | 18.2 | 30.3 | 50.4 |

| 625 | - | 4.0 | 5.3 | 8.0 | 12.0 | 20.0 | 33.3 |

| 650 | - | 2.4 | 3.2 | 4.7 | 7.1 | 11.8 | 19.7 |